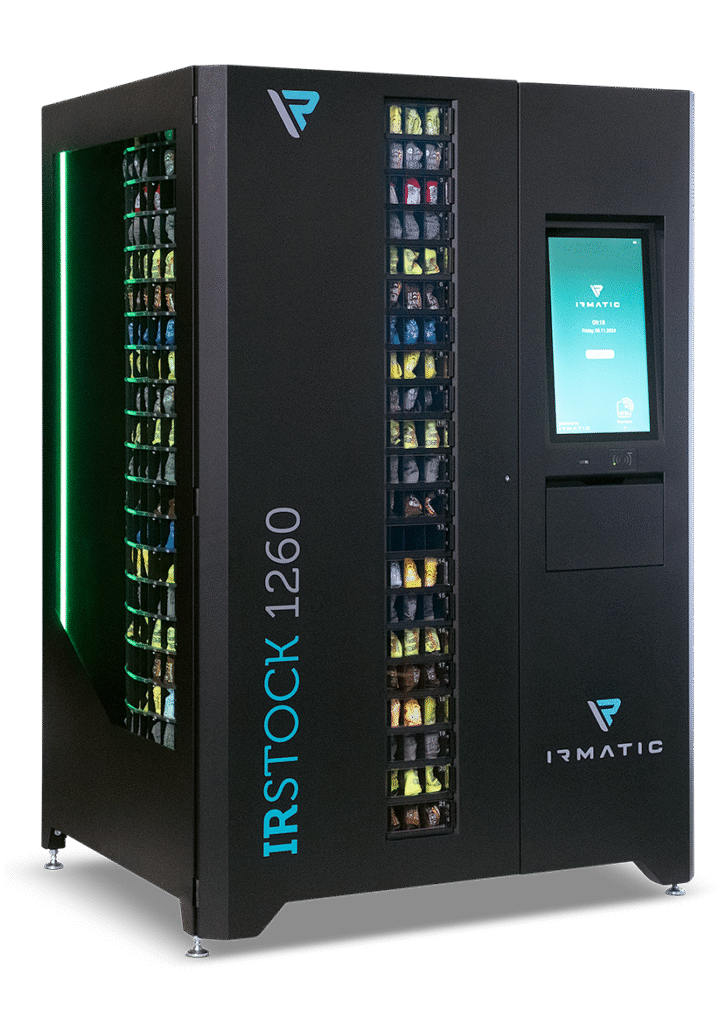

Industrial vending machines for dispensing welding supplies

Eliminate errors in dispensing welding supplies! Automate access to consumable welding products. Minimise mistakes, reduce waste, and maintain compliance with process specifications.

Why IRMATIC vending in the welding sector?

Precise identification of materials

Dispensing the correct wires and gas nozzles tailored to the specified technology.

Elimination of assembly errors

Operators receive only components compatible with the specific type of burner and source.

Unit consumption registration

Each withdrawal is archived with an assignment to a person, position, and project.

Support for technology version rotation

Distribution of components only in accordance with the current version of WPS/WPQR.

Limiting losses and misplacements

Withdrawals for stock and "just in case" are automatically blocked by the usage limits system.

Preparation for audits

Automatic documentation of inventory and access control of materials to production areas.

Industry Use Cases

Production of steel structures and tanks

Tips, sleeves, guides and connectors distributed by welding methods and ranges.

Robotized and automated welding

Components dedicated to specific robots, sources, and workstations – dispensing directly at the line.

Energy and heavy industry

Compliance of components with technological procedure requirements (WPS), elimination of non-conformities.

Repairs and maintenance

Quick access to spare parts and tips without the need to search in the stock.

Industrial vending machines for welding materials

Dispensing small, diverse welding components requires precision and full traceability.

Login at the workstation

Component release

Consumption or error report

Data enters the system

Increase control over welding materials! Leave your contact details – we will prepare an analysis of the application of industrial vending machines in your process.

Expert tips and articles

Więcej artykułów na bloguNOWOŚĆ!

Nowoczesny automat wrzutowy

26.05.2025

Jeszce więcej oszczędności. Dodatkowo: dbałośc o Twoje najbliższe środowisko