Modern production of industrial vending machines

Full production control is the foundation of the stability and reliability of our machines.

Universal application and wide configuration options

The production process of IRMATIC devices is designed for reliability, repeatability, and high precision. From mechanical construction to electronics integration and final testing – each phase is based on controlled industrial procedures, carried out in a modern manufacturing facility in Poland. The machines are produced in an end-to-end system – from design to a finished, operational device.

Functions and stages of the IRMATIC production process

Mechanical design and development

Each model of the machine is developed as an engineering project based on the analysis of implementation needs. The design team creates 3D documentation and technology sets tailored to the modular architecture of IRMATIC machines.

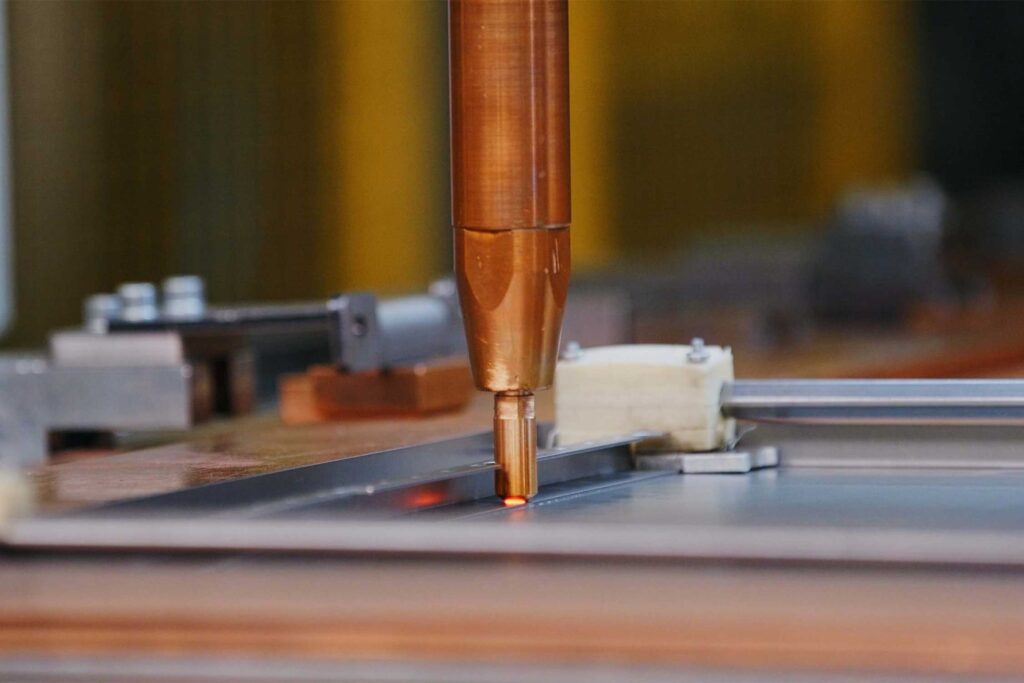

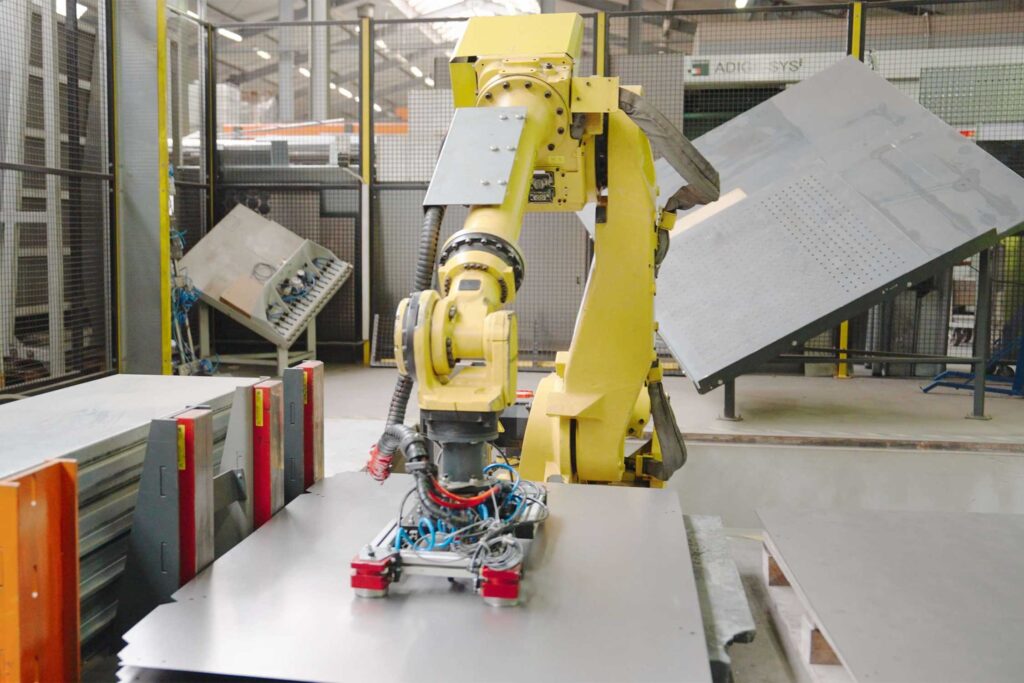

CNC machining and sheet metal bending

The device housings and mechanical components are produced locally – using CNC plotters, press brakes, and laser cutting. This ensures dimensional tolerance and high quality of workmanship.

Powder coating and component marking

Elements are coated in a closed-loop powder coating cycle. Component numbers and identification codes are applied automatically, in accordance with the parts inventory and batch tracking system.

Precise assembly of functional components

The installation of compartments, guides, drawers, and drums takes place at modular workstations. Each set complies with the individual specifications of the client, ensuring complete repeatability and adherence to documentation.

Installation of electronic systems and functional testing

Integration of screens, RFID readers, controllers, and sensors follows testing procedures. Each industrial vending machine undergoes a multi-level quality control test, including communication with IRSystem and functionality completeness.

Standardisation of logistics and packaging

Integration of screens, RFID readers, controllers, and sensors follows testing procedures. Each industrial vending machine undergoes a multi-level quality control test, including communication with IRSystem and functionality completeness.

Controlled quality. Always the same standard of execution.

Every IRMATIC machine leaves production as a ready-to-use device verified for quality, communication, and functionality. With a modular design system and internal production processes, we ensure a predictable delivery cycle, compatibility between models, and comprehensive service support based on component numbering.

Automate the dispensing of grinding wheels on the production floor! Contact our implementation engineer and analyse the current process.

NOWOŚĆ!

Nowoczesny automat wrzutowy

26.05.2025

Jeszce więcej oszczędności. Dodatkowo: dbałośc o Twoje najbliższe środowisko