IRSYSTEM management system

IRSYSTEM Warehouse Management System

Manage access to materials, tools, and components from IRMATIC machines and physical warehouses. Control who takes what and when, where assets are located, and when they return, through full audit trail and physical access features. No warehouse clerk, no chaos.

IRSYSTEM is more than traditional WMS systems

Centralized access control

Manage dispensing from vending machines and warehouse racks in one place – conveniently, transparently and securely.

Tracking of locations and statuses

Tools and components may be tagged with configurable statuses — such as: issued, in use, loading, repair — or any other custom labels defined in advance.

Vending + warehouse integration

Merge dispensing from vending machines and warehouse shelves into one process. IRSYSTEM enables issuing products from fixed warehouses via a menu on the device screen.

Electric lock control

IRSYSTEM – analogous to a machine’s proper compartment – opens warehouse doors. The mechanism protects assets from unauthorized access.

Manage rotation and product lifecycle

Plan reloads, maintenance and preventive replacements. Analyze usage cycles, withdrawal dates, and certifications to extend the life of assets as much as possible.

Automatic replenishments

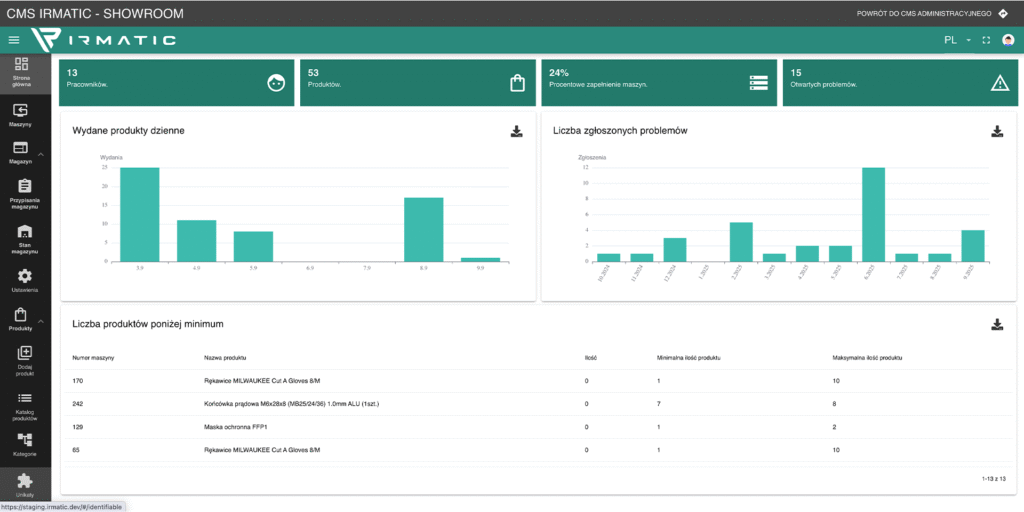

When a minimum threshold is exceeded, the system automatically generates a purchase order or notifies the appropriate department — without involving the warehouse.

Transparency and audits

Every resource movement is recorded: who, when, from where and why. Extensive configuration options ensure full compliance with ISO, IATF and industrial safety (BHP) standards and company procedures.

Analytics and inventory optimization

Receive clear reports on turnover, consumption and minimum levels. Support MRO, procurement and production departments in making accurate decisions.

Przykładowe zastosowania

Maintenance (MRO)

Technicians report a fault, and spare parts and tools are dispensed directly via the IRPOINT interface. The system opens the appropriate shelf or machine, and the issuance is confirmed by printed receipt — full control and rapid response to failures.

Multi-shift production

Operators have quick access to tools, materials, and components — whether they use a machine or warehouse shelf. IRSYSTEM automatically allocates consumption to the production line, work order or project, ensuring transparency and accountability.

Logistics and distribution

Easy preparation of material kits, dispensing directly from storage location, and full compliance control. The system prints location labels and tracks internal transport, eliminating the risk of mistakes.

Regeneration and recycling

IRSYSTEM supports the lifecycle of tools and materials intended for regeneration or recycling. Each item is assigned a status and life-cycle history — from receipt, through regeneration, to reuse or disposal.

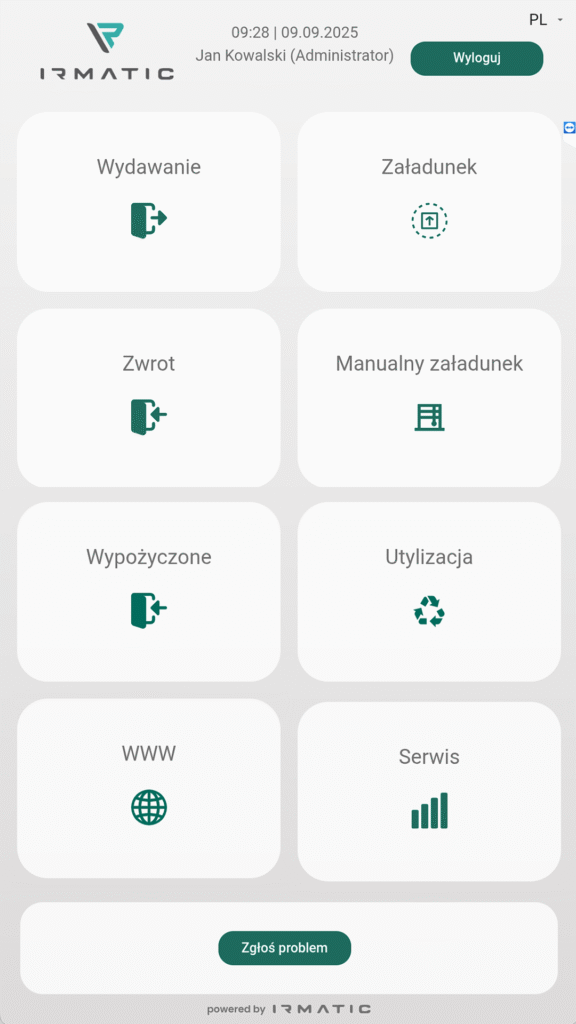

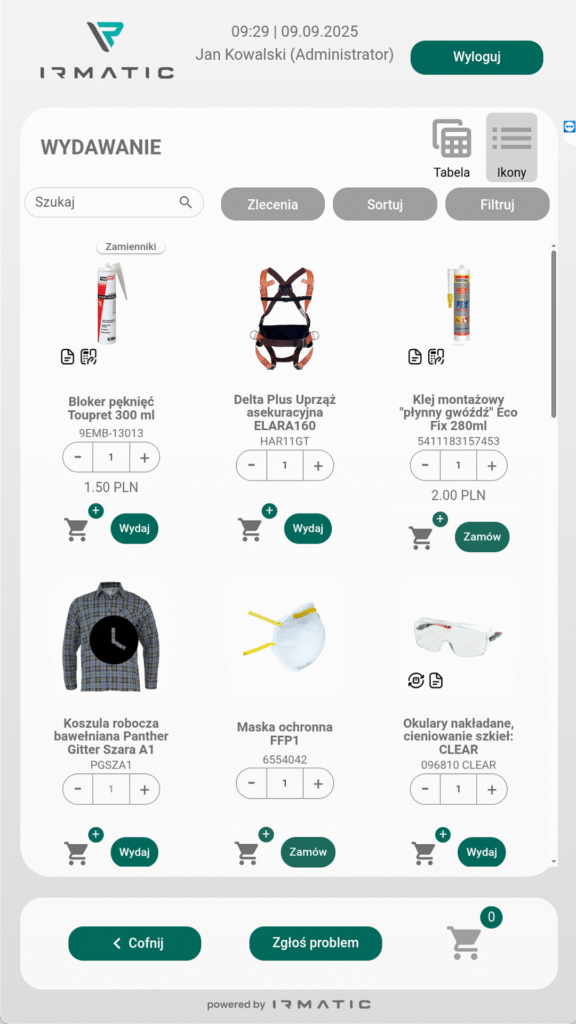

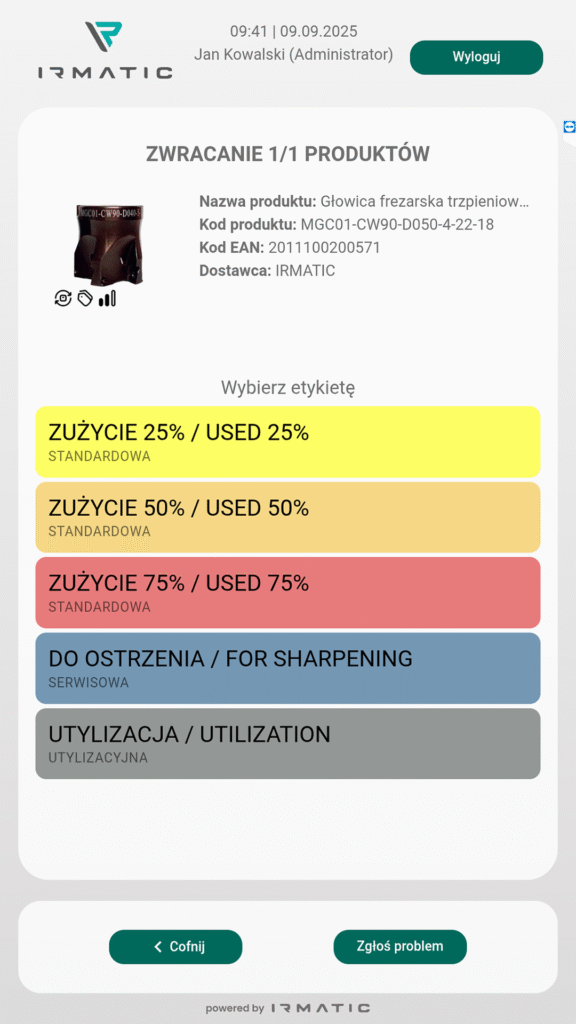

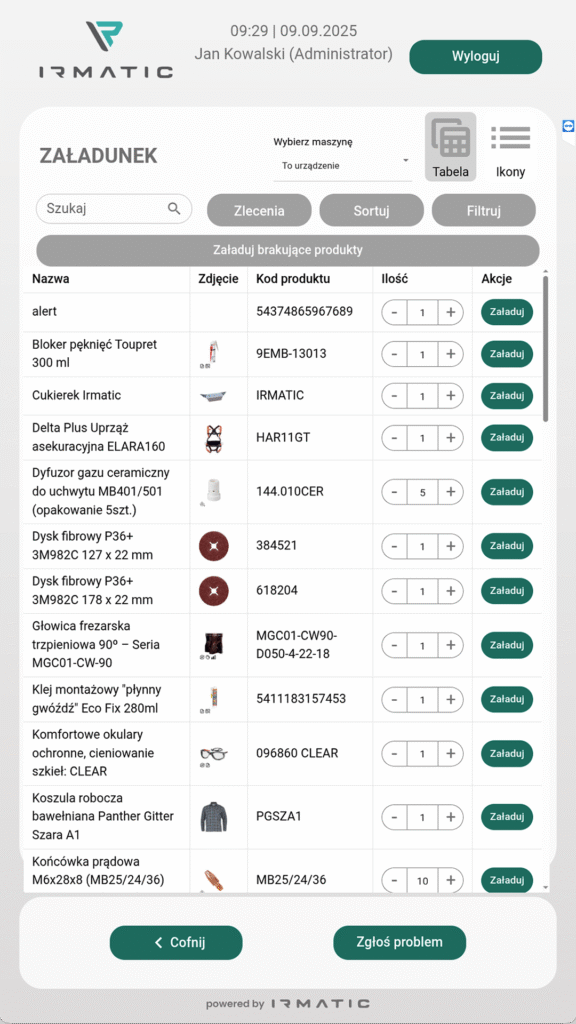

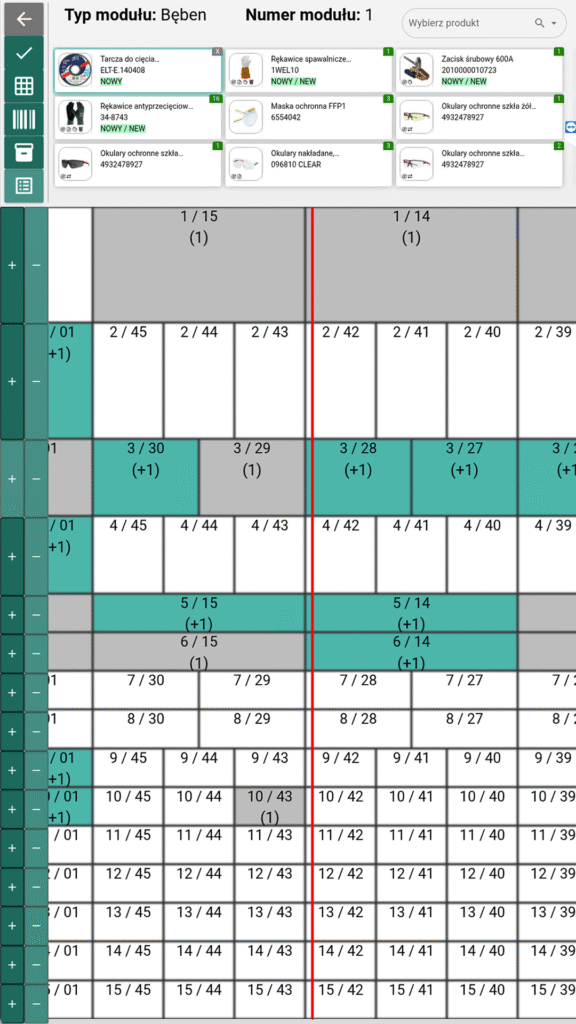

Interfejs obsługi automatu

IRSYSTEM supports login via RFID, password or network account. The entire interface is available in multiple languages, adapted to the work environment.

Action view tailored to user role and permissions. The system dynamically displays only features assigned to a specific group or position.

Fast search and responsive filtering of products. The user gains full control over outputs and orders via an intuitive interface.

IRSYSTEM presents catalog cards, PDF files, web pages, or test surveys. Everything in one place, available directly with the product.

During return, the system allows for the assignment of any labels: wear level, sharpening, disposal. The label configuration is fully flexible.

The operator sees a list of missing products along with codes and images. Detailed screens minimise the risk of errors.

IRMATIC machines support various loading methods: serial, manual, operator-based. The process is fast, scalable, and depends on the adopted procedure.

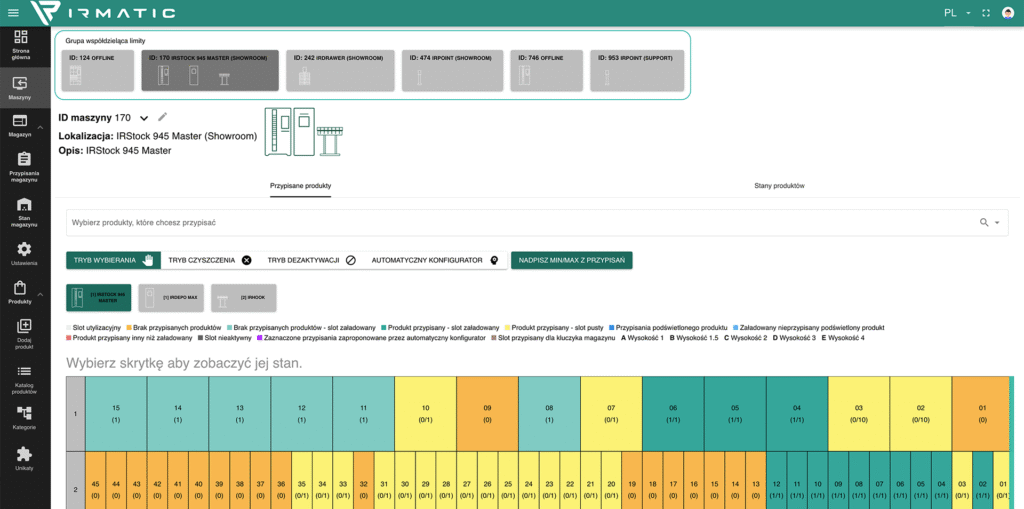

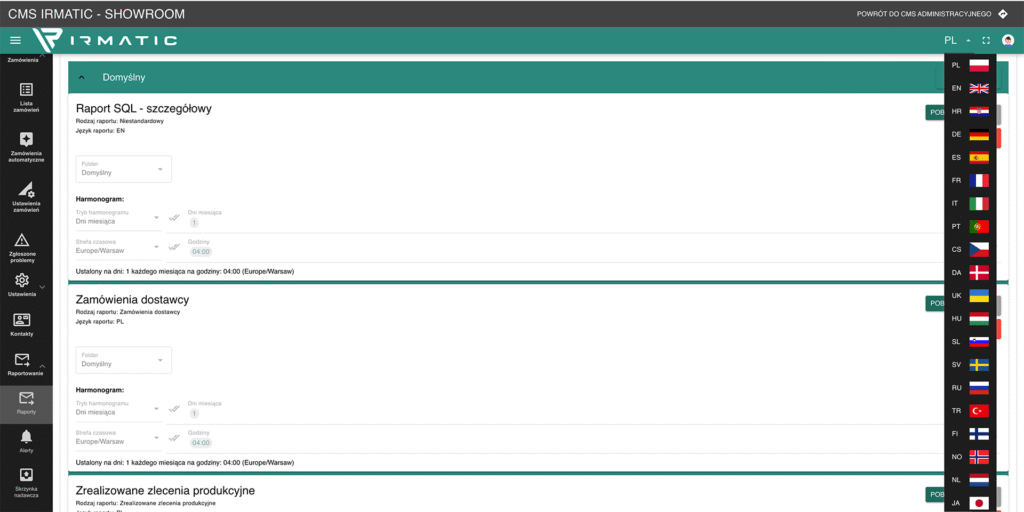

Interfejs systemu zarzadzającego

One place to manage sets of machines. Quickly check the locations, configurations, and status of individual devices across the entire infrastructure.

Flexible reporting system based on SQL. In addition to ready-made templates, it allows the creation of custom queries as needed, with support for multiple languages.

IRSYSTEM provides clear charts and indicators. It allows for quick analysis of dispensing history, planning of loadings, and forecasting of future demand.

ERP (SAP, Comarch, IFS, enova itp.)

TMS / WMS (transport i gospodarka magazynowa)

- Handling of location labels and tracking of internal movements

- Issuances confirmed from the IRPOINT or industrial vending machine

CMMS (maintenance, repair and operations)

- Recording of usage time for rotating tools

- Integration with the maintenance and inspection schedule

Active Directory / LDAP

- Integration with security policies

- Single sign-on (SSO) capability

Integrate vending and storage into one automated flow! Contact us to create a virtual tool crib and data-driven storage.

Expert tips and articles

Więcej artykułów na bloguNOWOŚĆ!

Nowoczesny automat wrzutowy

26.05.2025

Jeszce więcej oszczędności. Dodatkowo: dbałośc o Twoje najbliższe środowisko